The integration of robotics into manufacturing processes has revolutionized the way goods are produced, leading to increased efficiency, precision, and productivity. Robotics technology encompasses a diverse range of automated systems and machines designed to perform tasks traditionally carried out by human workers. From assembly lines to warehouses, robotics has become an indispensable component of modern manufacturing operations.

Enhanced Efficiency and Productivity

One of the most significant effects of robotics on manufacturing is the enhancement of efficiency and productivity. Industrial robots are capable of working tirelessly around the clock, executing repetitive tasks with speed and precision. By automating labor-intensive processes, robots can significantly increase production rates while minimizing errors and defects. This efficiency translates into reduced cycle times, increased output, and lower operational costs for manufacturers.

Improved Quality and Consistency

Robotics technology has also led to improvements in product quality and consistency. Unlike human workers, robots are not susceptible to fatigue, distraction, or variations in performance. This consistency ensures that each product meets stringent quality standards and specifications, leading to higher customer satisfaction and reduced waste. Advanced robotic systems equipped with sensors and vision systems can detect defects in real-time, allowing for immediate corrective actions and continuous process improvement.

Flexibility and Adaptability

In addition to efficiency and quality improvements, robotics has brought about greater flexibility and adaptability in manufacturing operations. Modern industrial robots are highly versatile and can be reprogrammed or reconfigured to perform different tasks or accommodate changes in production requirements. This flexibility enables manufacturers to respond quickly to shifting market demands, introduce new products, and optimize production processes for maximum efficiency and competitiveness.

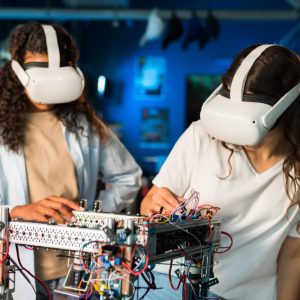

Safer Working Environments

Robotics technology has also contributed to safer working environments for manufacturing workers. By automating hazardous or physically demanding tasks, robots help reduce the risk of workplace injuries and accidents. Collaborative robots, or cobots, are specifically designed to work alongside human operators, enhancing safety while maximizing productivity. With built-in safety features such as sensors and automatic stop mechanisms, cobots can detect and react to human presence, minimizing the risk of collisions or injuries.

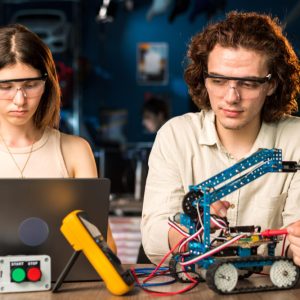

Job Creation and Workforce Development

Contrary to popular belief, the widespread adoption of robotics in manufacturing has not resulted in widespread job losses. While some repetitive and low-skilled positions may have been replaced by automated systems, the overall impact of robotics on employment has been more nuanced. Instead of eliminating jobs, robotics has led to the creation of new roles and opportunities in areas such as robot programming, maintenance, system integration, and process optimization. Furthermore, robotics technology has driven demand for skilled workers with expertise in robotics engineering, software development, and mechatronics.

Challenges and Considerations

Despite its many benefits, the integration of robotics into manufacturing also presents challenges and considerations. Implementation costs, including upfront investment in robotics hardware and software, as well as training and maintenance expenses, can be significant for manufacturers, particularly for small and medium-sized enterprises (SMEs). Additionally, concerns about job displacement, cybersecurity risks, and ethical implications of automation must be addressed to ensure responsible and sustainable adoption of robotics technology.

The Continued Evolution of Robotics in Manufacturing

Looking ahead, the future of robotics in manufacturing appears promising, with ongoing advancements in robotics technology driving innovation and transformation across the industry. Emerging trends such as collaborative robotics, artificial intelligence, machine learning, and digital twinning are poised to further revolutionize manufacturing operations, enabling greater efficiency, flexibility, and agility. As manufacturers continue to embrace robotics as a strategic asset, the role of robotics in shaping the future of manufacturing will only continue to expand and evolve.

Embracing the Robotic Revolution in Manufacturing

In conclusion, robotics has had a profound impact on manufacturing, revolutionizing processes, and reshaping the industry landscape. From enhancing efficiency and productivity to improving quality and safety, robotics technology offers numerous benefits for manufacturers seeking to stay competitive in today’s fast-paced global market. While challenges and considerations remain, the continued evolution of robotics holds tremendous potential for driving innovation, creating new opportunities, and shaping the future of manufacturing. As manufacturers embrace the robotic revolution, they position themselves for success in an increasingly automated and interconnected world.